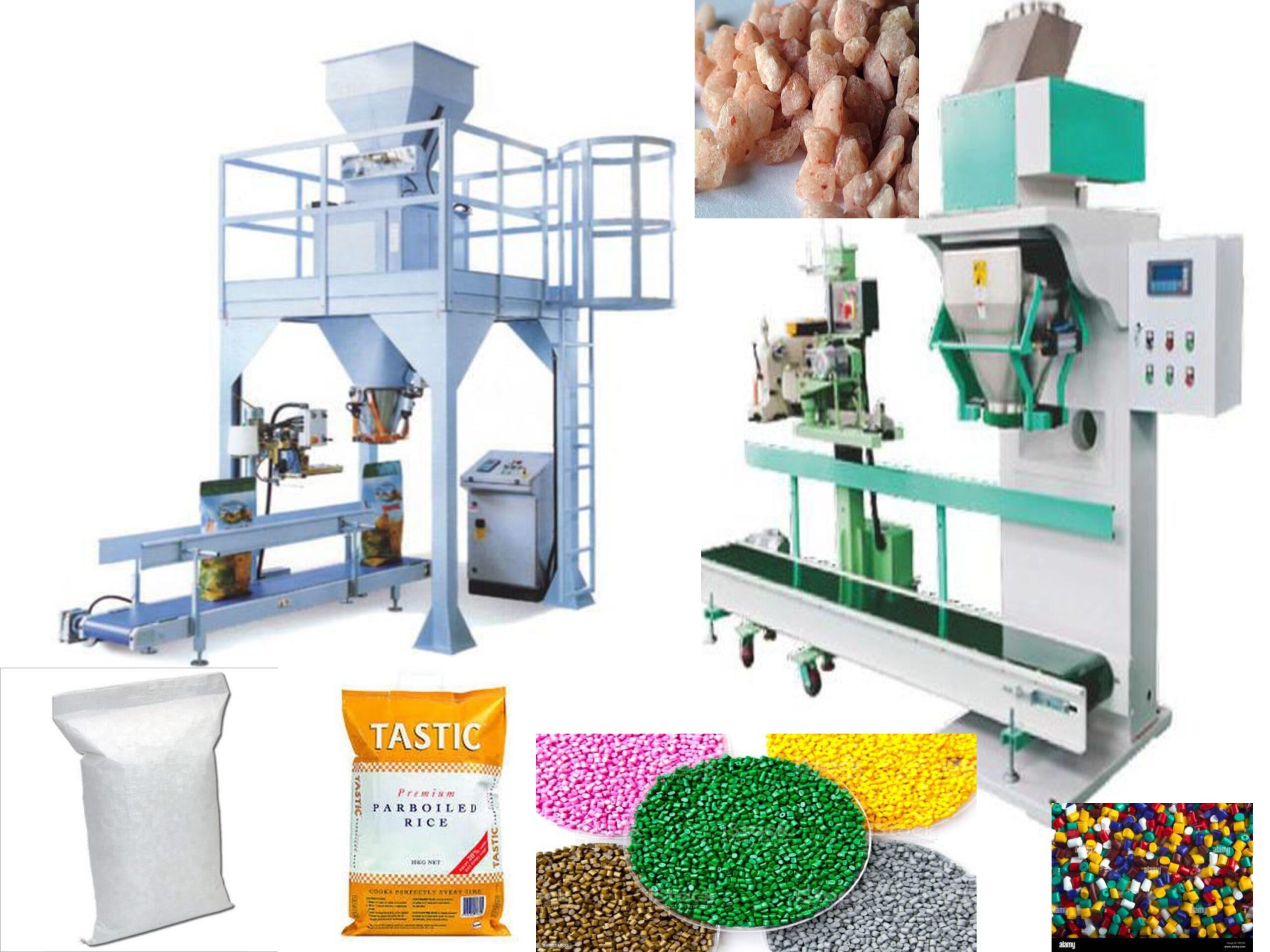

Bag filling machine

Key Features of Bag Filling Machines:

1. High-Speed Operation:

• Designed to fill bags quickly, reducing packaging time and improving throughput.

2. Accurate Weighing System:

• Integrated with precision weighing technology to ensure consistent bag weights, reducing material waste.

3. Versatility in Bag Types:

• Capable of filling various bag types, including woven polypropylene bags, paper bags, and polyethylene bags.

4. Customizable for Different Product Types:

• Can handle a range of materials, such as powders, granules, and seeds, offering flexibility in the production line.

5. Dust-Free Filling:

• Equipped with a dust-control system that minimizes spillage and ensures a clean working environment.

6. User-Friendly Interface:

• Intuitive control panels and settings allow easy operation, reducing the learning curve for operators.

7. Durable and Low-Maintenance:

• Built from high-quality materials that ensure longevity and minimal maintenance needs, maximizing uptime.

8. Automatic Bag Clamping and Release:

• Automation ensures that the bag is securely held during filling and automatically released once the process is complete.

9. Integration with Sealing or Stitching Machines:

• Seamless integration with sealing or stitching machines for a complete packaging solution.

Applications of Bag Filling Machines:

1. Agriculture:

• Ideal for filling bags with products like grains, seeds, fertilizers, and animal feed. The machine ensures precise filling to prevent spillage and wastage, which is critical for large-scale farming operations.

2. Food Industry:

• Used to package powdered and granular food items such as flour, spices, sugar, and rice. Its hygienic design meets food safety standards, making it suitable for food production environments.

3. Chemical Industry:

• Perfect for filling chemical powders, resins, and other sensitive materials that require careful handling. The dust-free feature ensures safety and cleanliness, which is vital in this sector.

4. Construction Materials:

• Suitable for packing products like cement, sand, and other construction materials that need quick and efficient filling to meet industrial demands.

5. Pharmaceuticals:

• Used for precise filling of pharmaceutical powders and granules, ensuring consistency in packaging for high-value products.

6. Mining Industry:

• Capable of handling bulk materials like minerals and ores, ensuring robust performance in heavy-duty environments.

Conclusion:

Bag filling machines are critical to improving efficiency, precision, and safety in packaging across various industries. At Vista Packing and Conveying Solutions, our machines are designed to meet the highest standards of quality and performance, ensuring that your production line runs smoothly and your products are packaged securely.